Kawasaki BA006NFE01 welding robot with Fronius TPS320i PULSE welding equipment.

Kawasaki's new BA006NFE01 arc welding robot, complete with Fronius TPS320I PULSE inverter pulsed welding machine and Fronius water cooled welding torch. The set is ready to weld, including torch harness inside the robot arm and through the hollow wrist.

For prices of Kawasaki Robots, click and complete registration

READY TO WELD SET WITH KAWASAKI BA006NFE02 WELDING ROBOT WITH FRONIUS TPS320I PULSE WELDING EQUIPMENT

Included in the delivery of this set are:

Kawasaki arc welding robot:

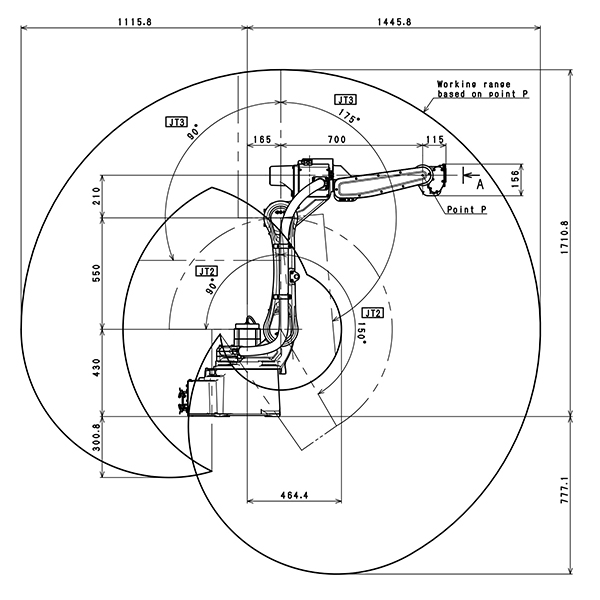

- Kawasaki BA006NFE02 arc welding robot (6 axes, payload 6 kg, repeatability ± 0.05 mm, reach Ø 2.890 mm)

- E02 Kawasaki robot controller

- Harness between robot arm en controller L=10m

- Teach Pendant with Harness L=10m

- Interface cabinet 32 inputs 32 outputs, digital signals to the welding machine, ethernet interface to the welding machine

Fronius lasapparatuur:

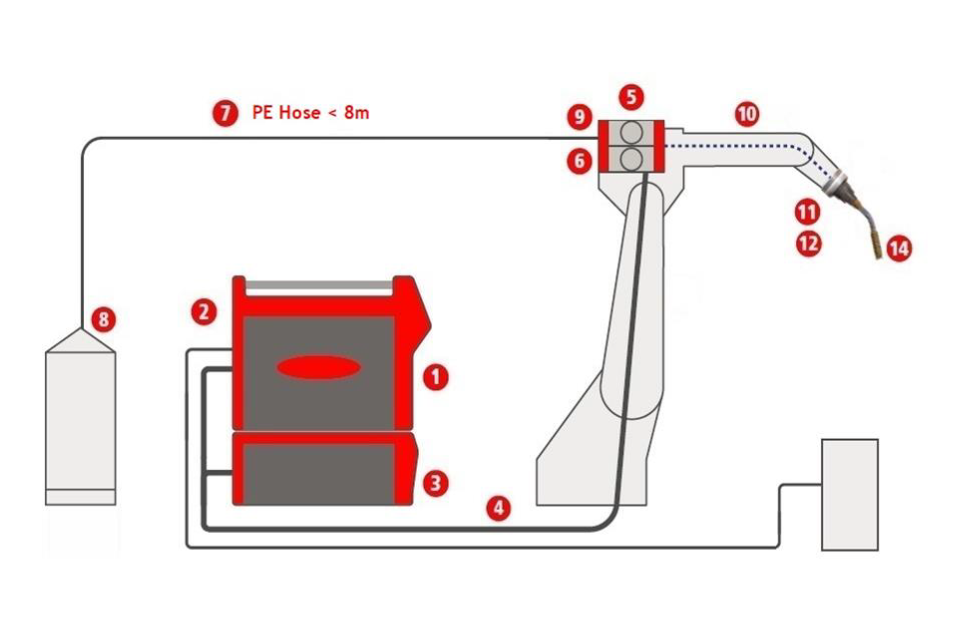

Pos Component

1 Fronius TPS 320i PULSE inverter controlled pulsed welding power source

2 Interface with the robot controller via Ethernet IP

3 Water cooling unit CU 1400i Pro/MC

4 Hose package from welding machine to wire feed unit L = 8 m

5 Wire feed unit, gas sensor, blowing valve

6 Bracket to attach the wire feed unit on the robot arm

7 Welding wire guiding

8 Coupling to welding wire drum

9 Coupling to wire feed unit

10 Hose package from wire feed unit to welding gun, trough upper arm robot and hollow wrist robot

11 Coupling to crash box

12 Fronius crash box for hollow wrist Kawasaki robot

13 MTB 500i W R/22°/L241/H50 water cooled Fronius push-welding gun

14 Gascup, grounding cable 70 mm2 L=10, gas reducing unit Ar/Co2

STEP INTO THE FUTIRE WITH KAWASAKI's NEW BA-SERIES ARC WELDING ROBOTS

Kawasaki Robotics reinvents itself with the dedicated arc welding BA-Series robots for easy operating and optimising arc welding processing.

BASED ON 40 YEARS OF ADVANCED ARC WELDING ENGINEERING

Kawasaki has been using arc welding robots for their own production (motorcycles, ship building, heavy construction) for many years. This vast experience was used to develop the new BA-Series arc welding robots.

HIGH SPEED, LIGHT WEIGHT RIGID ARM WITH LARGE REACH AND HOLLOW WRIST

An extremely compact and light-weight design forms the basis for high speeds and rigidity as well as an enormous reach. The BA-series have a hollow wrist for better guiding of welding torch cable.

ADVANCED CONTROLLER FOR ARC WELDING ROBOTS

Combined with a high-end control system, the BA-Series reliably meet the demands of the most varied arc welding fields, now and in the near & far future. These dedicated arc welding robot controllers are based on the well appreciated E-Series, with a slim design, high availability and reliability as well as the highly approved easy operation makes it ideal and efficient robotic welding systems.

FAST PROCESSING AND EASY ACCES TO FAST DATA STORAGE

Ultra-fast execution of programs, loading and storing processes as well as a precise continuous-path control and much more thanks to the up-to-date processor design and powerful components. 8 MB RAM (80,000 steps) and USB and TCP-IP Ethernet(2 ports) interface are standard.

USER FRIENDLY PROGRAMMING

Broad standard intuitive menu's and a simplified teaching screen helps to realize a fast startup and shorten the programming time.

EASY OPERATION

Motor power ON and program start may be activated directly via the teach pendant. The clear colour display with two parallel information screens (e.g. position and signal data) facilitates the process control.

ADVANCED FEATURES SUPPORT THE OPERATOR

Within the integrated data base welding data and parameters can easily be stored and the integrated welding interface realizes direct connection between welding controller and robot. Additional functions as the “start sequence function” lead to an easy operation. The “restart sequence function” sends robot back to the position where the welding was interrupted and restarts the process with an automatically overlapping welding.

COMPACT UPGRADABLE AND USER-FRIENDLY

Multiple external axes may be integrated. All established bus systems (Interbus, Profibus, ProfiNet…) are supported. The integrated Soft PLC may be edited via the teach pendant or even more comfortably at a (Tablet)PC. Custom-tailored user interfaces may be programmed using Kawasaki's powerful AS programming language and used for the simplified control of the robot and also peripheral devices.

EASY Maintenance

Due to the optimized modular configuration of the Kawasaki controller, maintenance work is exceptionally user-friendly. Furthermore integrated service and diagnosis tools guarantee increased safety in operation. Remote diagnosis via Ethernet is also included in the standard package.

PRICE LIST KAWASAKI ROBOTS

The prices of the Kawasaki Robots will become visible after the registration is completed, click and complete: registration

Data sheet

You might also like